Briefing

PRINTED FUNCTIONAL STRUCTURES ON STEEL STRIPS

TASK

Your task is it to identify and explain fields of application (large scale) for this technology. What value delivers your idea? In which industry could the technology be applied?

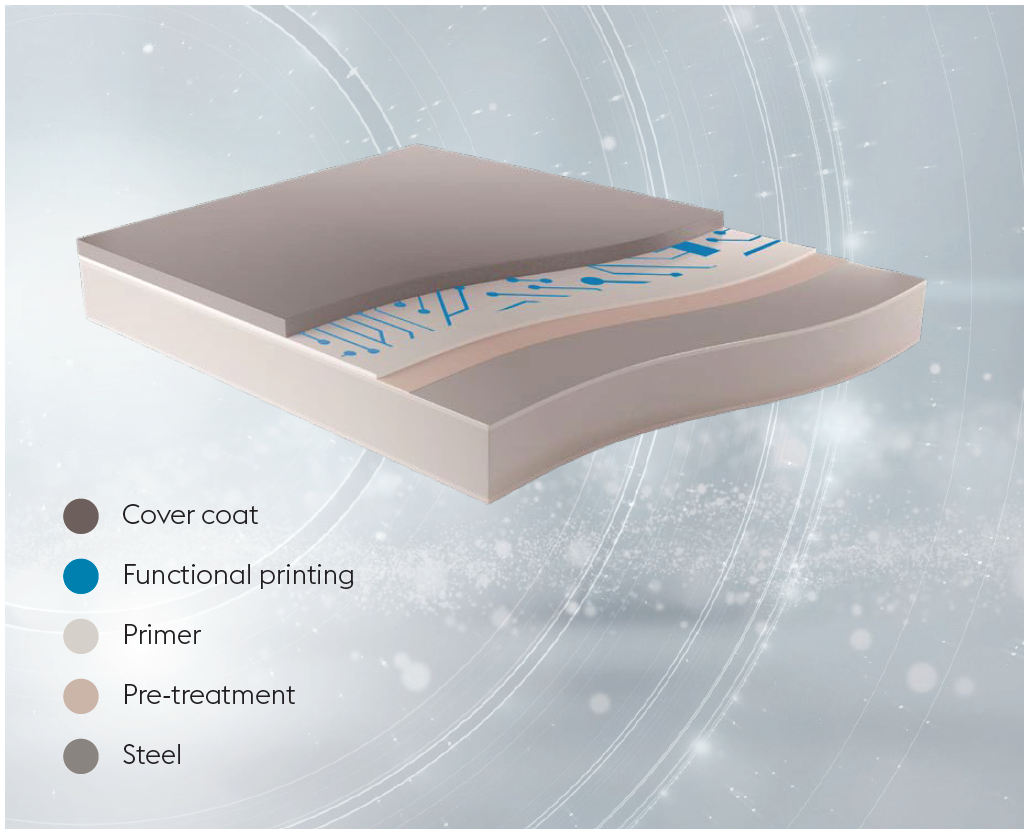

TECHNOLOGICAL PRINCIPLE

With the newly developed process of functional printing on steel, conductive structures can be applied in a roll-to-roll process to the coated steel strip. The application roll represents the size of one electronic structure, the maximum size of one pattern equals the circumference of the roll and can be repeated endlessly. For different use cases different application rolls will be designed. As the production line is situated in an industrial environment, it has to be a rugged design of the structure. This means that the functional electronic structures must be wider than 0.5 mm and in the thickness range of 3 – 10 µm. On top of the electronic structures a top coat is applied, so that the electronic structure is fully integrated into the painting. For the top coat a wide variety of different colors and structures can be used. The curing process for the coating needs about one minute at ca. 200 °C. As substrate for the functional printing steel strips with a thickness of 0.4 – 2.5 mm and a width of 900 – 1.730 mm can be used.

The new use cases should allow designs of big structures for one application or big numbers of smaller applications, that the surface is sufficient for an industrial process of functional printing on steel.

ADDITIONAL FUNCTIONALITIES

One field of application of printed functional structures embedded in steel coating comprises all forms of heating. This includes indoor heating, temperature regulated surfaces as well as thawing of snow or ice covers. Thawing of snow and ice can be imagined, both, in outdoor applications (e.g., on rooftops) and in indoor applications (e.g., in fridges). Another example is the prevention of condensation.

Another potential field of application is dealing with surfaces that can be used as control elements. The control elements are embedded capacitive sensors in (almost) arbitrary shape and size. If desired, they could also be formed to possess a certain shape. On a very basic level, the touch of a finger can be detected and used to trigger any action. For example, lights can be switched on or off by just touching the wall with the integrated sensor. A further example is the opening (or closing) of doors or shutters with an embedded touch sensors.

The field of monitoring describes applications where the deformation or destruction of steel surfaces can be monitored. Critical deformations of, e.g., facades or other construction elements can be recognized. The integration of this new application possibility could prevent future failures and accidents. Furthermore, the breakthrough of a steel shell/panel, caused by vandalism or burglary attempts, leads to a tear through of the embedded conductive structures, which can be easily detected.

“Measuring” (to that date) comprises temperature and liquid film measurement. By using this technology, the temperature of a certain spot can be measured by embedding a resistive temperature sensor into the coating layer. The measurement of a liquid film refers to the detection of water films or even small water droplets on the coated steel surface. Even on large area steel panels, small water droplets can be detected. Furthermore, the filling level in containers can be measured.

WIDE VARIETY OF PROCESSING POSSIBILITIES

The steel sheets or steel panels with integrated conductive structures can be reshaped with a wide variety of common forming process like every standard organic-coated steel strip.